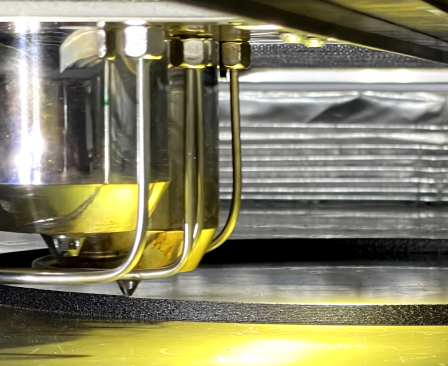

Our advanced technology makes it possible to obtain products and results which are not obtainable anywhere else

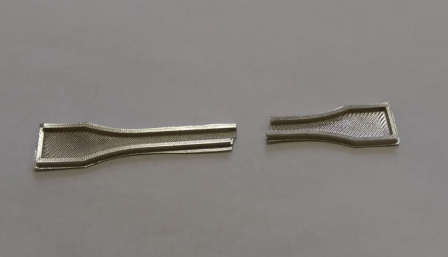

Tooling, molds, jigs

There are challenges in tooling manufacture:

- Difficulty in manufacturing, resulting in long lead times.

- High cost of tooling.

One way to solve these challenges has been the use of AM. This makes it possible to significantly reduce the lead time and the cost of tooling.

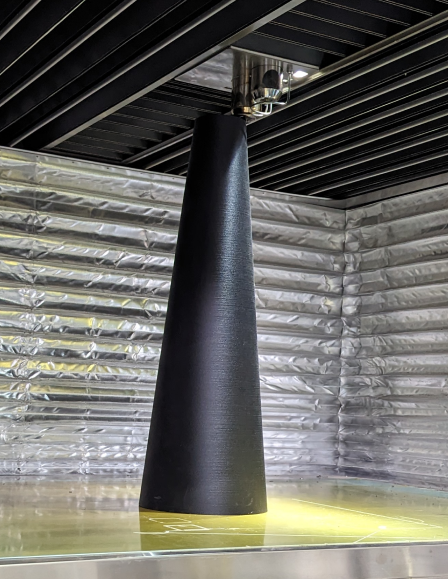

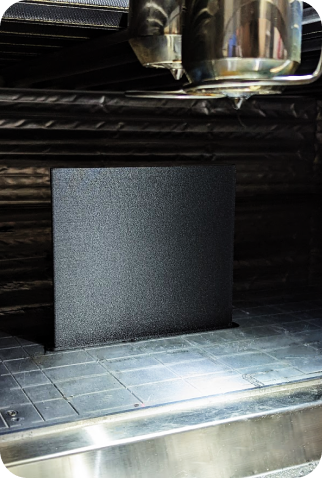

The Gigaprinter is uniquely suited to this for a number of reasons:

- Wide range of options for balancing speed and surface quality according to part requirements.

- Creates a plastic master model from a 3D model of the final metal product – much faster than milling.

- Plastic master models are much stronger than lost wax master models used for metal casting.

- Can print from PMMA with an ash residue of only 2% by weight.

- Production of monolithic, large-format master models possible.

- Perfect for use in research and development to create single master models or small lots.

- Significantly lower burning temperature and simpler technique than burning master models from a range of resins produced on photopolymer printers.

- Plastic master models absorb less moisture and are easier to store than wood, which requires constant temperature and humidity.